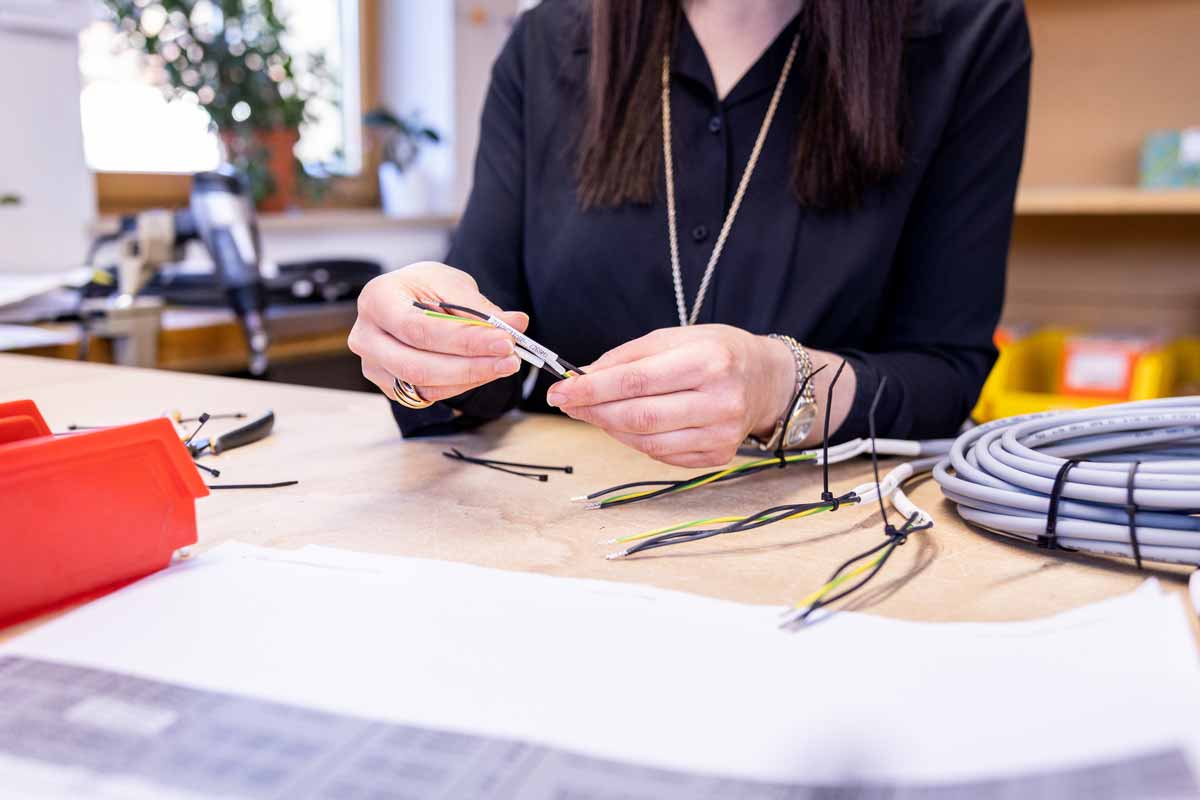

Professional cable assembly – Efficient complete solutions

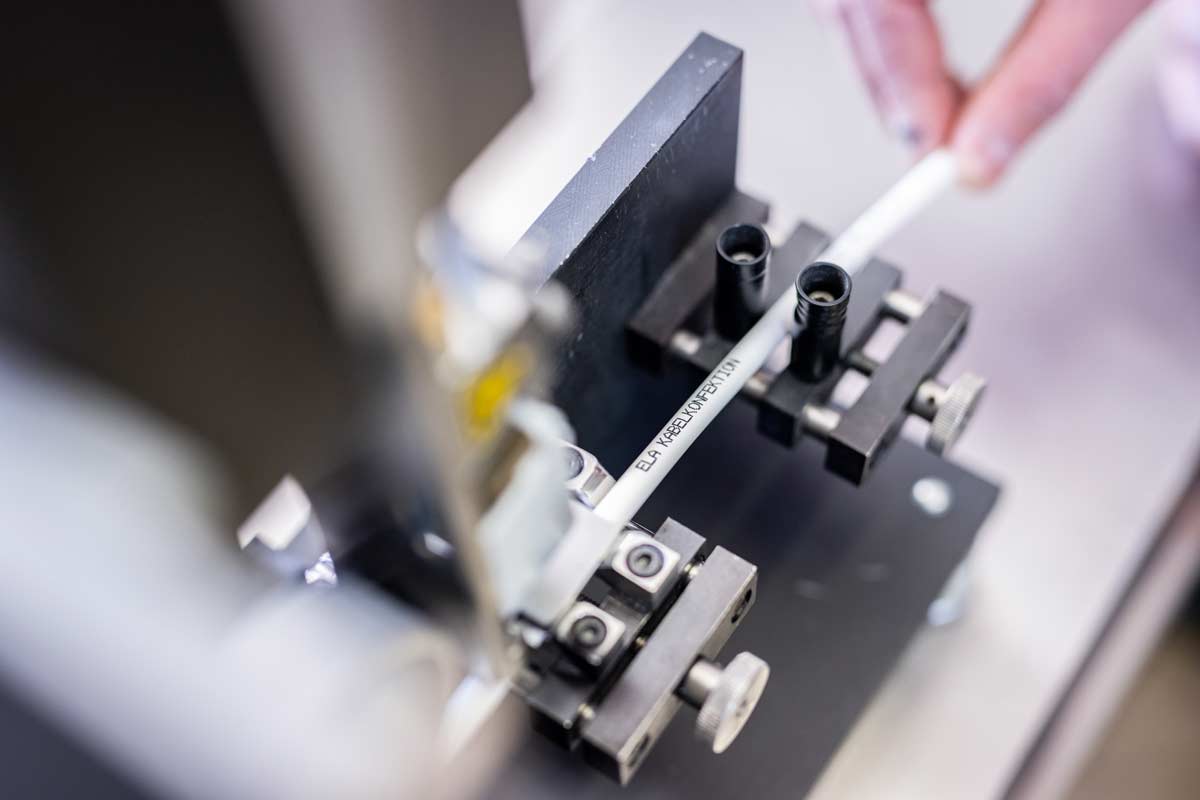

As experts in cable assembly, component manufacturing and control technology, we transform highly complex electrotechnical requirements into individual, ready-made complete or individual solutions. We do all this in a single operation and under our own roof.

More than 30 years of experience in the fields of cable processing, electrical engineering and control cabinet construction enable us to achieve particularly low-maintenance and thus economical solutions for companies in a wide range of industries. Nothing stands in the way of use at worldwide locations, as we meet the requirements of several international approvals such as UL approval, CSA approval, EN approval and Swiss railroad approval.